TOKAI Solid Tire's solid cushion press on tires have been keeping forklifts running in the US, Japan, Europe, Southeast Asia and all over the world for decades, and they're well-liked by everyone from distributors to dealers to end users precisely because of the quality that comes from our intensive engineering and TQM QC processes.

Of course there are about a billion different press on tire brands available out there from God knows who all. Some are great, some are garbage, and most you just don't know what to make of, so we put together a quick FAQ on TOKAI

Solid Tire press on band tires to give you some background on why you should email us at mailto:[email protected] or call us at +66 95 642 6994 to try them out.

Many years ago, when the Earth was young, one of our lajor clients came to us and said, "We can never have a broken band. Ever." We're the largest importer of solid rubber industrial tires into this country and

it's one of the largest economies in the world, so that's a lot of press on bands that have to never fail.

Of course you've said this yourself to whomever you buy from, right? It's one of the first things

any serious distributor discusses with a manufacturer.

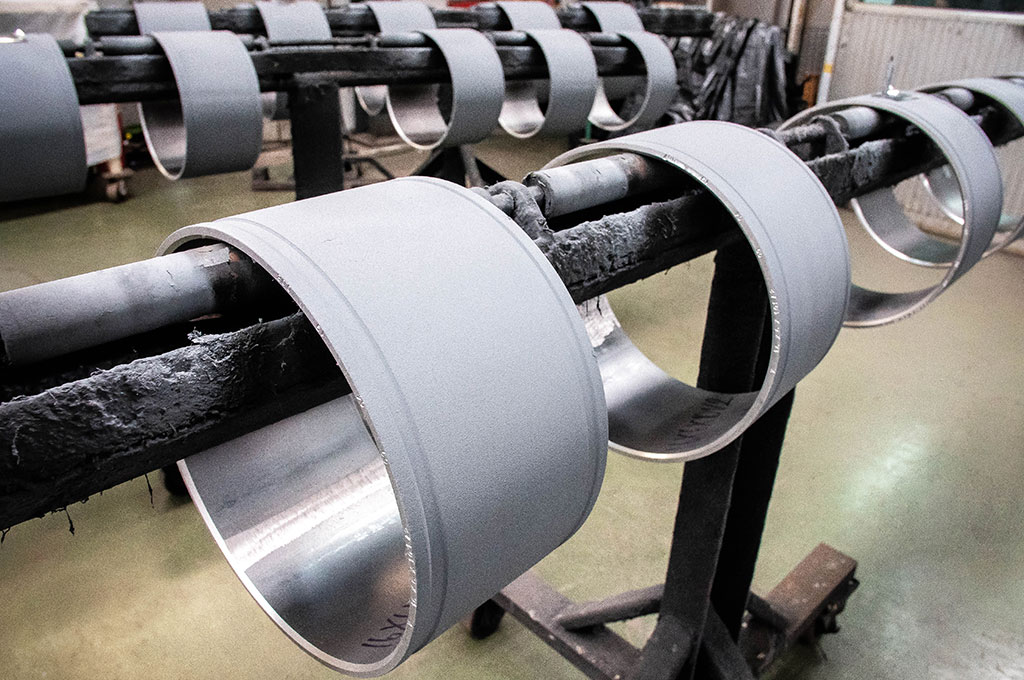

So, we worked together directly with this customer to create a process that re-works every single band after it arrives at our factory.

The

bands arrive arc-welded, which is fine and shouldn't have problems, but when you can never, ever have a broken band, you have to do more.

First, we clean every single band by hand and then cut the arc

weld on every band and re-weld it, ensuring that the newer, stronger weld will hold.

The band is then grooved on the edge to give the tread an extra guard against slippage.

Finally, the band is

tested with a special chemcial before being sent on to the bonding department for another cleaning followed by Chemlok application.

This just isn't something that most manufacturers would do, but if you

come visit us in Thailand you'll see it all day, every day, all year, because we make a huge number of these tires and it takes a lot of work to get it right.

And why? Because a customer once asked us

to make sure we never have a broken band and we cared enough to do something about it.

We're different like that. We don't make me-too press on tires and we don't treat you like a me-too customer. Relationships,

like properly engineered press on metal bands, matter to us.

The next question we get asked by every customer is, "Do you know how to bond metal to rubber?" Apparerntly some manufacturer's don't, which seems nuts to our people, but it must be true since we get asked this

every time.

The answer, as mentioned above, is, "Yeah, we do it thousands of times per day across all of our product lines."

It's a pretty simple process, but it has to be done right.

First,

we take the re-worked metal bands and clean them, after which they are passed into the bonding section of the factory, an enclosed area where the workers wear PPE to protect them from Chemlok, which you definitely

do not want to breathe on a daily basis.

The Chemlok is applied using regularly tested sprayers, then the bands are sent to let the application process finish.

Finally, every single band is measured

to ensure that the proper amount of Chemlok was applied so that the rubber doesn't come off. Nobody wants that to happen!

That happens with thousands of press on bands, metal track links and other products

every day in our five-football field large factory and we take it seriously every single time.

So, yes, you can rest-assured that we know how to bond metal to rubber!

When we tell customers that our standard black tread layer is, other than additives needed to make a tire, pretty much made of all-natural rubber they almost don't believe it, until they take a look at the finish

when the tire rolls out of the container.

See, over time, one way a lot of tires have become cheaper (or more profitable for factories) is by taking out natural rubber and putting in other stuff.

Sometimes, in some applications that's a good thing - and we do that too, where it makes sense for our customers - but our basic tread layer hasn't been touched in many. many years, except to make minor improvements

in the oils and additives that go into any part of a tire.

Thailand produces more natural rubber than any country in the world, look it up, and that's why we can afford to make such a high quality tire

with all-natural rubber. It's also why when oil prices skyrocket, we don't need to worry about raising the cost of our tires the way some factories who rely heavily on synthetic rubber might.

Natural

rubber, among other things, provides greater rebound resilience, meaning that every time that tread rolls down under pressure and then rolls back up, the natural rubber takes less of a beating than synthetic

rubber would. Additionally, natural rubber holds together better after getting gashed or ripped on. When you see cracks or tears in a synthetic tire you can start the clock on it, while a natural rubber tire

taking a beating from cuts and rips is more likely to hold together and not fail.

You just can't beat all-natural Thai rubber, and that's why we use it - you should too.

The first sign that you're dealing with a BS tire is when the factory salesman tells you, "Oh yeah, it'll beat the crap outta the Continental." At TOKAI our policy is we don't trash other people's product and, in

fact, our engineers and designers think very highly of several premium press on tires out there, which the TOKAI Solid Tire press on band tire has competed directly against in national markets - and outperformed

on a quality at cost-per-hour basis.

Our standard construction, all-purpose compound press on runs very well in most applications, and wears better in certain applications than some of the most well-known

tires, at a price that's considerably more affordable. Keep in mind, this is not a budget tire, it's a value-priced premium tire. It's also a problem-solving tire, due to the many compounds available for different

applications, so if you're interested in getting more for less - and exactly what you want, instead of exactly what they make.

People often ask us, "What's your warranty?" and the answer is one of those answers that's so simple that it flummoxes a lot of folks:

If we broke it, we'll fix it. Period.

Just like

any other company, large or small, we've turned out a bad product here and there over several decades, and when we have - you can ask our customers - we've studied the situation, put our engineers on it, looked

up every detail of production for that tire (we keep extensive records on every single tire, what goes into it, how it got made and who made it) and if we did something wrong then we've warrantied the tire.

Done deal.

We know in a world of 12 page warranties citing everything from act of God to international terrorism you're used to seeing a telephone book's worth of language to explain a very simple

concept like "we stand behind our products," but we think it's best not to complicate the obvious and just say, you know, we stand behind our product.

Anyone who needs a ten page contract to tell you

how they stand behind their product, well, the other 9,000 words in there probably aren't there to explain how they stand behind their product.